Mistra Future Fashion can now reveal breakthrough results after six years of research within textile recycling. It is an important milestone towards the future of global textile recycling systems necessary to enable circularity for fashion and textiles.

For the first time new viscose filaments from cotton are demonstrated, produced by a successful chemical recycling process of polyester/cotton fiber blends. The process is called Blend Re:wind – and generates three circular outgoing product streams. Cotton is turned into new high quality viscose filaments and polyester into two pure new monomers.

This is a result from six years of research within Mistra Future Fashion and plays an important role in future global textile recycling systems. The project focuses on chemical recycling of polyester/cotton (polycotton) fiber blends with the objective to separate and generate relevant outputs for future industrial use; polyester monomers and a cotton pulp suitable for regeneration into cellulosic textile fibers (such as viscose fibers). The full name of the process is ”Blend Re:wind – a Swedish process for the recycling of polycotton blended textiles”.

”Our separation process, Blend Re:wind, is developed having existing industrial processes in mind, and our aim is to integrate as much as possible to minimize both environmental and economic costs, while boosting businesses. Scaling up from lab scale is the biggest challenge at the moment, and it is also costly. The integration possibilities of the Blend Re:wind process would however address these challenges in feasible ways.”

“There are many brilliant recycling innovations in progress globally at the moment, highly needed for successful future recycling systems. Different processes will most probably be needed and we hope that Blend Re:wind is one of these on the global market in the future.”

Dr Hanna de la Motte, theme leader for theme 4, Recycling, within Mistra Future Fashion and research scientist at RISE.

FACTs – the Blend Re:wind process include:

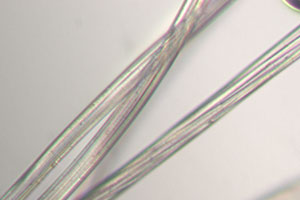

- High quality of the recycled filaments: Key focus has been on the cotton recycling stream and to produce high quality viscose filaments from the separated cotton residue, which is crucial for further industrial processing towards recycled fabrics.

- Successful complete recycling of polycotton blends with pure product streams at high yield: Viscose filaments have successfully been obtained from cotton separated from worn-out polycotton sheets. The filaments have the same quality as filaments made from commercial dissolving pulp used in existing viscose production. The separated polyester residue, polyester monomers, can be re-polymerized into high quality polyester. The monomers are suitable for integration with existing chemicals processes – partnerships are established and experiments performed.

- Good feasibility with existing industry processes: A strong benefit with this process is that the separation takes existing industries into consideration, and the aim is integration with existing forest and chemical industries, or other recycling options. The separation uses chemicals already utilized in the Swedish forest industry, and in the viscose industry, to facilitate possible integrations.

- Strong environmental performance: It is a suitable separation process since it is water based and uses only common, cheap bulk chemicals and a catalyst.

Facts about the research and the Blend Re:wind process:

- Blend Re:wind was initiated in 2011 and has been developed in the Swedish Mistra Future Fashion by the Chalmers University of Technology, RISE Research Institutes of Sweden and the international forest industry group Södra.

- The research has been pursued by Dr Hanna de la Motte, theme leader for theme 4, Recycling, Mistra Future Fashion and researcher at RISE. Her expertise is within cellulose chemistry and textile recycling, where she is an internationally recognized expert. Further key involved persons are Dr Anna Palme, researcher and scientific leader at Chalmers and Dr Harald Brelid, advisor and inventor from Södra.

- The project budget is 600 000 EUR which has been funded in Mistra Future Fashion with funds from the MISTRA research foundation, RISE Circle Economy Centre of Excellence, and in-kind contribution from involved partners.

The project has contributed with new scientific knowledge for chemical textile recycling and scientific publications:

Theses

Recycling of cotton textiles: Characterization, pretreatment, and purification

Doctoral thesis by Anna Palme, Department of Chemistry and Chemical Engineering, CHALMERS UNIVERSITY OF TECHNOLOGY Gothenburg, Sweden, 2017 Link

Separation for regeneration – Chemical recycling of cotton and polyester textiles

Master’s thesis by Stina Björquist, UNIVERSITY OF BORÅS, Faculty of Textiles, Engineering and Business, Sweden, 2017

Towards Recycling of Textile Fibers – Separation and Characterization of Textile Fibers and Blends

Master’s thesis by Anna Peterson, Department of Chemistry and Chemical Engineering , CHALMERS UNIVERSITY OF TECHNOLOGY Gothenburg, Sweden 2015

Scientific article

Palme, A., Peterson, A., de la Motte, H. et al. Development of an efficient route for combined recycling of PET and cotton from mixed fabrics. Textiles and Clothing Sustainability (2017) 3:4. Link

The results have also been rewarded with three awards:

Environmental Stipendium 2017 by Renova

An annual award which aims to promote research within environment and recycling.

To Anna Palme – Anna’s research is about recycling textiles of the polyester / cotton blend, a material used in the hospital’s bed sheets. Polyester and cotton mixed fabrics should not be thrown without recycling into new textiles! This is the goal of Anna Palmes research. “Recycling is complicated by the fact that textiles are made in a variety of materials, which are often mixed,” says Anna Palme, PhD at the Department of Forestry Chemical Engineering at Chalmers. Link

Young Investigator Award 2017 for 5th EPNOE International Polysaccharide Conference in Jena

To Anna Palme – Recovery of cotton cellulose from polyester/cotton mixed textiles “For excellent research as reviewed by the scientific and programme committees and presented at the 5th EPNOE conference 2017”

Environmental Stipendium 2017 by Textilia

To Stina Björquist – Separation for regeneration: Chemical recycling of cotton and polyester textiles

For more information:

Dr Hanna de la Motte, theme leader Mistra Future Fashion and researcher at RISE Research Institutes of Sweden, hanna.delamotte@ri.se

Sigrid Barnekow, Program Director Mistra Future Fashion, +46 703955468, sigrid.barnekow@mistrafuturefashion.com