sustainable fashion

The term sustainable fashion is widely used in communication today. The interpretation of its meaning most likely differs depending on interest, profession and level of knowledge. The concept can be perceived difficult to grasp due to its abstract description and the low possibility to assess garments’ direct impact. How does one behave sustainably as a consumer or even as a producer?

multiple definitions of “sustainable fashion”

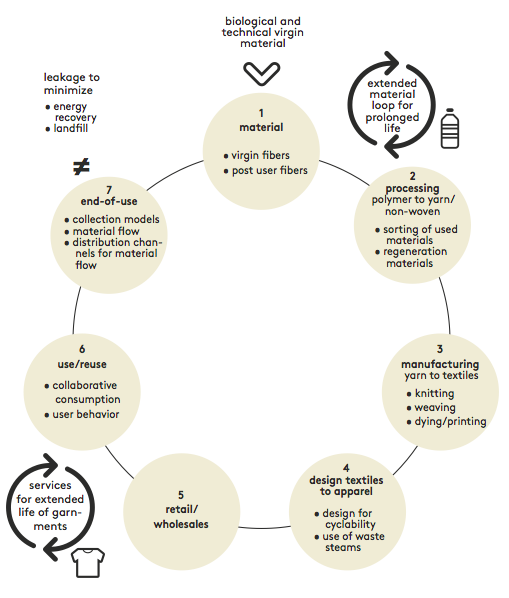

Some say it is an oxymoron, in the light of growing consumerism and the advancement of fast fashion. Some say it is about producing clothes in an environmentally and socio-economically sustainable manner, but also to consume in a more sustainable way. The conscious behavioral patterns and attitudes we as users have while consuming. Sustainable fashion is also about aiming for a circular economy, i.e. the possibility to close the loop by looping everything in the value chain, by using bio based materials from sustainably managed resources or by recycling.

To achieve systemic, sustainable change in the fashion industry is one of our key sustainability challenges of our time. This change is like a giant puzzle, where all pieces need to be re-shaped, finding new matching pieces and in time allowing a new design to appear.

“When envisioning a sustainable future, we’ll get new perspective on our garments. Showing respect to the garment becomes the golden ticket for sustainability; to enable profitable system, sustainable consumption habits and a production process (including recycling) with circularity. Instead of earning money solely via one time purchases, it is about creating additional value throughout the whole value chain.”

“By wearing fashion we express who we are and our view of the world. If today fashion is about expressing our support of unsustainable consumption, behavior and unawareness, then tomorrow it is a powerful tool to spread awareness of sustainability and circularity.”

why

Fashion faces severe global environmental and social challenges. Consumerism is driven by population growth and economic development. The world population is expected to reach 9.2 billion in 2050 and the number of middle-class consumers is expected to triple by 2030. The growing volumes in fashion mean that the already significant environmental impact from the fashion industry is increasing, especially from the use of water and chemicals in cotton cultivation and production. Innovative solutions are needed to solve or improve the environmental issues of highest importance (water, energy use and climate change, and toxic chemicals).

The world-wide quest for sustainable textile fibers is a current challenge for the fashion industry with lots of question marks that are still unanswered. How, when, and to what can recycled fibers be used? What is the technical performance of the “new sustainable fibers” that are marketed today? Are we sure that the sustainability performance of these fibers is higher than for the old alternatives? As consumer how can I act sustainable and what can I expect from the producers to enable sustainable actions? How can the society support with stimulating policies or supporting textile collections systems for recycling? How can a producer still generate profit in a world with more reuse focus? What types of new business models can appear? And how will these become attractive by consumers? How do we secure to close the loop, what do we do with worn-out waste? The questions are many and there is no one-fix-all solution. Transforming a system requires time, engagement and focus.

circular economy

The envisioned change is guided by the concept of circular economy. Instead of today’s linear structure where each business and production process is individually optimized, the circular economy focuses on how to maximize the processes collectively and secure as low environmental impact as possible. It means resource minimization and efficient resource use. Products and materials are designed to be upgraded or re-circulated and used again through as many cycles as possible. It implies intentionally designed systems where products are linked to materials cycles and designed for disassembly and re-purposing. The concept is closely related to Cradle-to-Cradle, Closed Loop, Blue Economy and other similar concepts.

throughout a garments lifecycle

from start

Textile Fibres. Global demand for clothing increases with the population growth and a rapidly increasing middle class. The production of textile fibers faces significant resource constraints. Cotton and polyester constitute more than 90% of the textile materials. Cotton is problematic due to the heavy use of water, pesticides and fertilizers. Polyester is problematic as well as it derived from finite fossil resources, ie we are emptying the planet’s pockets.

New alternative fibers are under development. At present there is experimentation with new fibers, like paper, milk, seaweed, soy etc. These have all shown to be great sustainable alternatives. The manufactured cellulosic fibers have steady increased the last years, but the current rate of demand is not fast enough to offset the production rate on cotton. Cellulose material has large potential and the dissolvent fabrics are waiting for new products to develop from their dissolvent pulp. Recent research such as advanced life-cycle-assessment allows better understanding of impact due to its use of water and ecosystem resources like forests. It confirms that forest-based fibers are justified, but more research is still needed.

in process

Textile Fibres to Garment Production. Life-cycle-assessment that is used in order to assess a product’s or service’s environmental impact throughout its value chain, shows that it is the production process that causes the main environmental burden in the life cycle of clothes. The vast majority of manufacturing is outsourced to low-cost locations. The Swedish fashion industry is today characterized by fashion brands that import products manufactured mainly in China, Turkey and Bangladesh (Statistics Sweden, 2014). The textile supply chain is often described as long and complex and includes several production steps from the sewing factories back to dye houses, weaving mills, yarn spinning mills and fiber producers. The most possible development steps with the largest environmental improvement potential are: 1) more sustainable fibres, 2) less energy intensive yarn and fabric production, 3) more sustainable wet treatment and 4) production of garments with longer life-span. But influence supply actors and enable a change in production is not easy to manage. Approx 96% of fashion companies in Sweden have less than 10 employees why possibility to change current structure and standards abroad are understandable low.

The fashion industry faces several challenges how to measure environmental impact and it is thus assessed in many ways. For example there are many definitions on sustainable water use and there is not only one way to assess water in a life-cycle-assessment. Currently the standards for assessing environmental impact of clothing, the so called Product Category Rules (PCR) needs improvement there are as shortage of PCRs for garments hinder the access to data and proper assessment. Social concerns and environmental impacts have stimulated various attempts introduce initiatives and standards, such as STWI, BSCI, The Swedish Chemicals Group, GOTS, Higg Index, Sustainable Apparel Coalition, Better Cotton Initiative, Clean Clothes Campaign, Fair Wear Foundation, DressCode, NICE, SCAP, Made-By etc.

in use

The Swedish consumer buys around 10 kg of clothes per year. 8 kg of textiles goes to waste and only 3 kg goes to reuse. Consumers could act sustainable by using the garments for longer and by ensuring that unloved but reusable garments reach recycling systems. The impact of such changes could be large. To illustrate the effect, if an average garment stays in use 3 times longer than today, its carbon footprint is reduced by 65% and its water use by 66%.

There are several ways in which garments could be kept in use for a longer time. Manufacturers could help by creating more durable garments and by providing pro-longing services. Consumers could help by using the garments for longer and by ensuring that unloved but reusable garments reach recycling systems. The impact of such changes could be large. To illustrate the effect, if an average garment stays in use 3 times longer than today, its carbon footprint is reduced by 65% and its water use by 66%.

Consumers can already today act sustainably. First immediate action is to reflect ongoing about what to wear and the responsibility the consumers hold for the garments. Instead of making “sustainable” choices only when they shop, consumers ought to reflect and act on how to optimize the length of use, including beyond their part of the usage period.

- Care for it to enable re-use by others

- Enable further use by providing it to resellers

- Consider transportation mode when shopping

- Ask producers for more information on their sustainable work

- Utilize wearing as statement of being sustainable

- Invest into garments that are of high quality (to enable long life-span)

- Ask social bodies for standardized infrastructure for worn-out garments/ waste

discarded

Reuse & Recycling. Reuse means garments that are enabled a longer life and usage by an additional user/s. The collection and receiver of the discarded clothing are primarily charity organizations and second-hand organizations/companies. This is the preferred use of discarded garments as most often clothing that are put as discarded there is still possibility for longer usage before the quality is equal to worn-out. Once the garment is put as waste, next step is to recycle it.

To enable recycling all textiles needs sorting. Today most textile sorting is performed outside the Nordic countries, where labor costs are lower since the sorting process is currently highly labor intense. All sorting is done in greater scale manually but automatic sorting is requested in order to efficiently manage the bigger amount of textiles that recycling (especially chemical recycling) require. This automatic sorting system needs detectors of material categorization, ie new detection methods and new marking of textiles

To achieve a circular flow of materials, the discarded textiles must be recycled into new textiles. Today there are no large scale industrial processes for new textiles. This will lead to an open loop system, where input of virgin materials is required.

Little collection and recycling of non-reusable textiles occur in Sweden today. The existing recycling techniques are primarily used for handling textile waste is energy recovery (incineration). There is where most of Swedish textile waste ends up today either due to deficiencies in the collection of consumer textile waste and sorting of household waste, or due to a limitation of optional recycling process. Today some mechanical recycling can be seen, this means it is teared apart, and most goes to rags, padding or insulation, so called “down-cycling”, but also to newly spun thread, the so called “fibre-to-fibre recycling”. Mechanical fibre-to-fibre recycling, like making old cotton textile fibres to new cotton fibres, is considered difficult to reach viability as these have significantly lower quality than virgin fibres. Today there is in demo scale production and the regenerated cotton fibres are mixed with virgin cotton fibre threads in order to get to needed quality of strength, with the mix of 20% regenerated fibres, 80% virgin. Existing chemical recycling, ie chemicals is used to reformulate the fibres, of cotton takes place in lab-scale today. But polyester recycling is already in full scale in Asia.

Textiles suitable for mechanical recycling are denim jeans, cotton garments and home textiles, pure polyester garments and home textiles and garments with high wool content. Note that only spandex-free denim jeans can undergo mechanical fibre recycling while jeans with spandex are converted to insulation.

During the user phase most textile materials is broken down by wear, washing and heat-drying, which lowers the quality of the fibres prior to recycling. Fibre quality is crucial for how the material can be recycled. Similarly chemical recycling of cotton and cellulosic man-made fibres is limited to the number of times that the material can be circulated.

Recycling process of blends is the biggest challenge where mechanical recycling could be done either by handling the material as a whole or to separate out the different materials from each other in a pre-stage. Apart from the challenge with decrease in quality in mechanical treatment, another challenge regards the fact that the synthetic fibre normally is stronger than the natural fibre. This leads to inhomogeneous process and it also requires more energy. As a result material blends are nor recycled today.

Today, recycled polyester is marketed in-store however this polyester is recycled from PET-bottles, not polyester textiles. The only commercial recycling route of polyester is performed by the company Teijin in Japan however the amount in comparison to total masses of consumed textiles still very low.